- Disposable Surgical Mask 3 Layers/3 folds and elastic , highly resistant, of blue/ green color;

- Comes with elastic loops for securing the ears and metal strip covered in plastic for nose bridge;

- Protects the carriers against bacterial transmission, against splashes with bodily fluids and prevents their transmission from health care workers to patient or from one person to another;

- Allows air flow, ensures breathing without restrictions, effortless and is an efficient filtering barrier;

- Odorless, fiberglass-free and latex free.

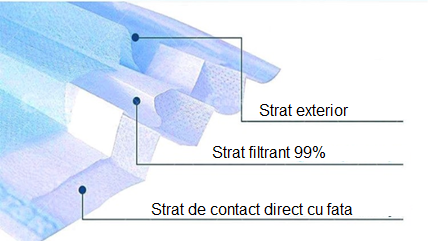

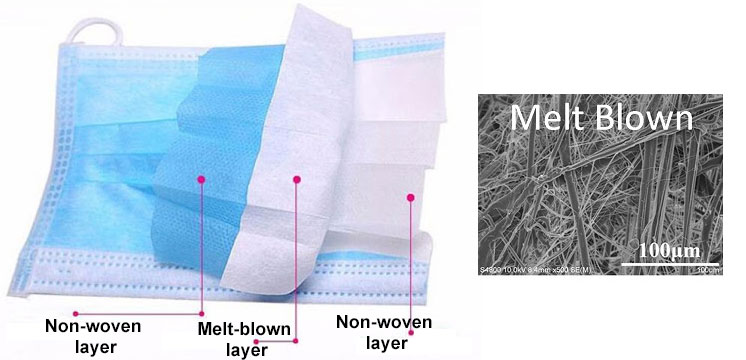

Materials

- Outer layer of non-woven fabric of spunbonded polypropylene (PP) type, of blue/ green color;

- Face-contacting layer of non-woven fabric of spunbonded polypropylene (PP) type, of white color;

- Particle-filter layer of non-woven fabric of melt-blown polypropylene (PP) type, of white color, bacterial filtration efficiency (BFE) ≥ 98%;

- Mask accessory – metal strip for a perfect fit to the shape of the face, made of single-core galvanized wire, covered in PE;

- Mask accessory- elastic loops for ears, made of elastic (nylon), with diameter of 2.5 – 3 mm, pull resistance 1:2.5-3.

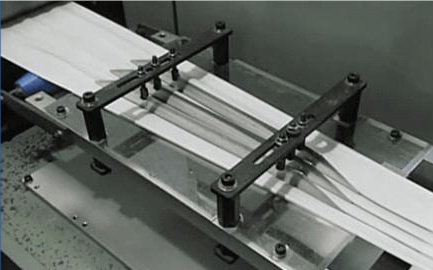

Technological Process

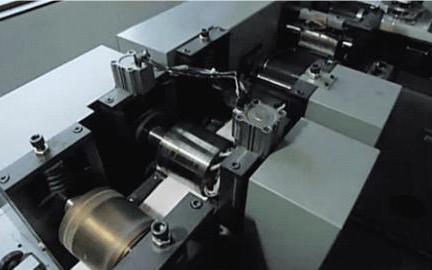

1st Stage

Overlapping the three layers of non-woven fabric.

2nd Stage

Inserting the metal strip for nose bridge and support.

3rd Stage

Making the three folds of the mask.

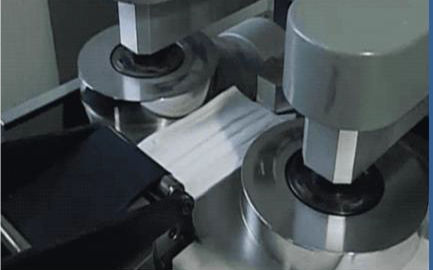

4th Stage

Pressing the folds for a correct alignment.

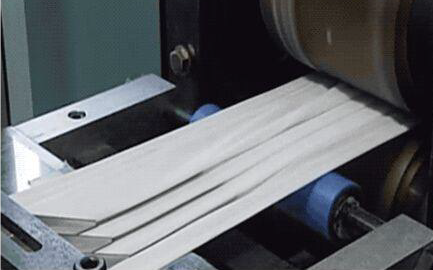

5th Stage

Cutting to length.

6th Stage

Welding on the outline.

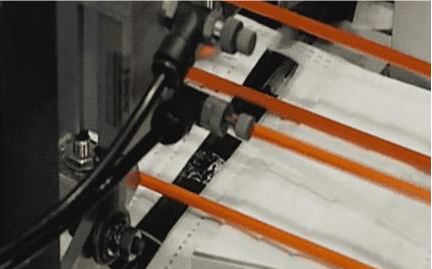

7th Stage

Cutting to the final sizes of the product.

8th Stage

Ultrasonic welding of the elastics that form the ear loops.